Product|Gut Ware Company

Simple rubber product

Many of our products are sealing parts while there are many kinds of simple rubber products generally used in the industry. Selecting good sealing parts is significant because severe airtightness is required for its proper use. We manufacture sealing products using vacuum press molding machine to prevent them from having a surface problem. Rubber itself is diverse in functionality depending on what to blend (multiple kinds of chemical agents) even if its shape, condition, and polymer are the same. We also design blending on our own, so we can provide a rubber material dedicated to each customer to be suitable for your use.

LF (Low Friction) rubber

Use of LF (Low Friction) rubber makes it possible to reduce frictional resistance of the surface and keep the elasticity at the same time. There are few possible risks of the surface being "peeled off" because no coating is performed on it. If It should happen, the rubber bleeds from inside, so the surface can be gradually restored.

※Time necessary for restoration varies depending on workplace environments. So, please try it in your workplace environment prior to purchase.

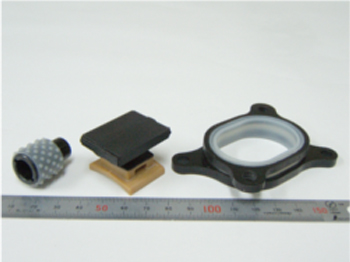

Rubber composite product

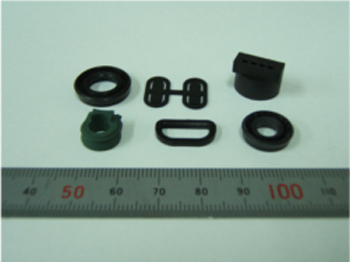

We can provide a customer with a composite product by compounding other material into rubber. We apply indirect bonding method (vulcanization bonding) that compounds materials inside a mold. It is possible for us to compound multiple materials into rubber. Various materials such as iron (S45C, SPCC, etc.), aluminum alloy, brass, SUS, PTFE, phenolic resin, PPE, PA, PPS can be compounded into rubber. It is our great asset that we can compound conflicting materials such as thermosetting rubber and thermoplastic resin. We promise to provide a customer with a product which realizes your ideal.

FEM Analysis

We support your product design, analyzing rubber displacement, stress, etc. by computer after applying load, pressure, and heat to rubber.

Product

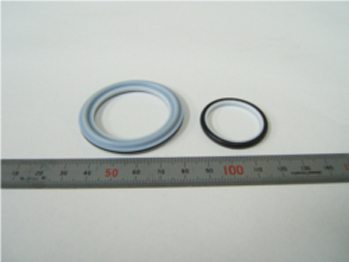

Composite product of PTFE and rubber

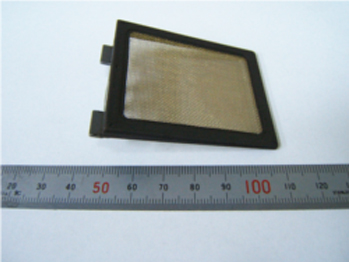

Composite product of brass mesh, metal frame and rubber

Composite product of aluminum and rubber

Thermoplastic elastomer product

Precision sealing product

Composite product of thermoplastic resin and rubber

Low repulsive rubber (low sulfur)

Type of rubber

- NBR

- H-NBR

- X-NBR

- Acrylic rubber

- Fluorocarbon rubber

- EPDM

- Natural rubber

- SBR

- Butyl rubber

- Silicon rubber

- Chloroprene rubber

Experience of Compounding

- Rubber + SPCC

- Rubber + Aluminum die- casting

- Rubber + SUS 304

- Rubber + Brass mesh + SWP

- Rubber + PTFE

- Rubber + Aluminum Die Cast + PTFE + SPCC

- Rubber + 66 Nylon + SAE 1065

- Rubber + PPE

- Rubber + PPS + PTFE

- Rubber + Phenolic resin

- Rubber + Phenolic resin + SPCC + Brass

- Rubber + Brass

- Rubber + SUM